Ống Quan Sát chất lỏng Plast-O-Matic

.jpg)

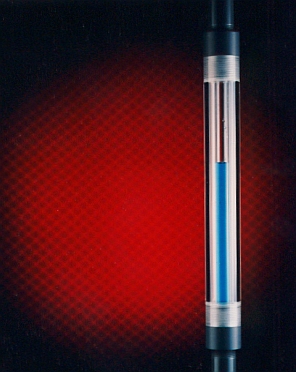

Plast-O-Matic chemical flow and level indicators offer a safe and economical means of indicating flow, clarity , or exact level of extremely corrosive and ultra-pure liquids such as sulphuric acid, hydrochloric acid, chlorine, caustics, and demineralized water.

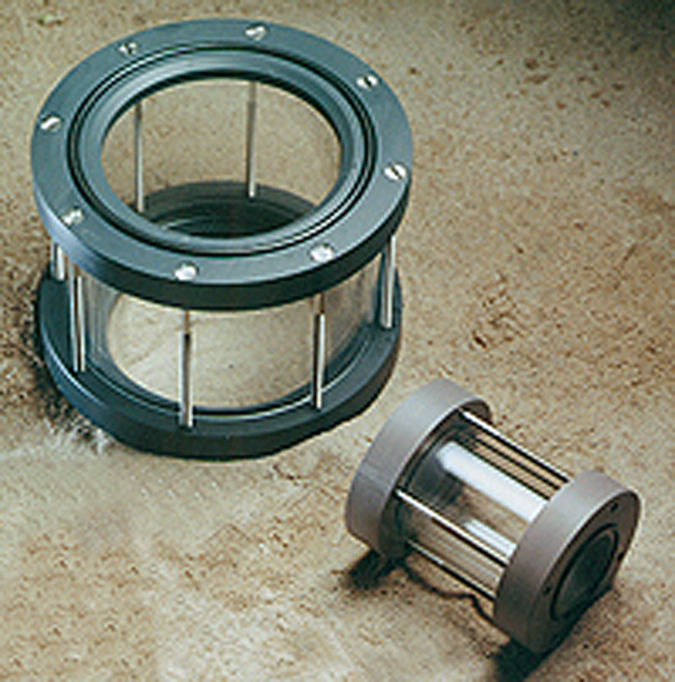

Two essential considerations in the choice of a flow or level indicator should be its strength and design simplicity since these factors minimize malfunctions and maintenance problems. All Plast-O-Matic flow and level indicators are designed to withstand reasonable external shocks. Simplicity is their engineering standard. These flow indicators are available in three different models: Series GX single-wall sight glass, Series GY double-wall sight glass, and Series GYW double-wall, wafer-style sight glass. The level indicators are available in one model: Series GL. All are easy to install, practically maintenance free, and above all, easy to view whenever necessary.

Advantages of Plast-O-Matic Flow and Level Indicators:

·Large 360° viewing area.

·Series "GY," "GYW" and "GL" have double wall construction for maximum safety.

·Full flow design (no corners to collect debris).

·Wide choice of select plastic materials to assure maximum chemical compatibility.

·Little or no maintenance required.

·No special hardware required for installation (completely assembled and pre-tested).

Design Features

True Blue® flow and level indicators are designed to indicate the presence or clarity of liquid in a piping system or to indicate level in a tank. They offer a maximum viewing area with a full 360° visibility for dependable observation and inspection from a reasonable distance.

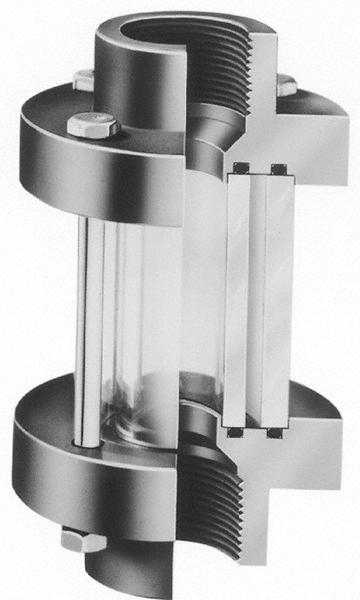

With the exception of the Series "GX" flow indicator, which can only be used for liquids compatible with acrylic, all Plast-O-Matic indicators utilize a double wall construction. All inner walls are Pyrex® for maximum corrosion resistance, and all outer walls are high impact acrylic which acts as an armored shield against external shocks.

The inner transparent cylinder walls used in the Series "GY," "GYW" and "GL" indicators are Pyrex, a borosilicate glass of very low alkali content that resists attack from most bases and acids with the exception of hydrofluoric acid and sodium hydroxide. This is the same material used in manufacturing glass pipe that is extensively used in the chemical, food, beverage and pharmaceutical industries.

The outer transparent cylinder walls used in all PLAST-O-MATIC indicators are manufactured of a high impact strength acrylic. This material possesses uniform optical quality and has an extremely high light transmission factor, which is of great importance when the color or clarity of your liquid is a prime consideration. Acrylic cylinder walls are ultra-violet resistant.

O-ring seals are used on all PLAST-O-MATIC indicators allowing them to seal at extremely low pressures as well as high pressures. In the Series "GYW"wafer style flow indicators, O-ring seals are also supplied for both ends eliminating the need for flange gaskets.

All Plast-O-Matic flow indicators are full ported, eliminating any possible flow resistance.

They are available with an optional mechanical fluttering device to indicate the presence of flow that would otherwise be difficult to see (please see "Fluttering Devices" section).

Stainless steel compatible sight glasses with grounding straps and other features are available by special order.

Installation Considerations

All Plast-O-Matic flow and level indicators are easily installed in a piping system. The flow indicators may be installed either vertically or horizontally; however, the level indicators can only be installed vertically.

Both the Series "GX" and Series "GY" flow indicators are simply threaded into a piping system. They should only be connected to plastic fittings. Male threads should be wrapped with PTFE tape or other acceptable pipe sealant and only made hand-tight, followed by a one-quarter turn more using a strap wrench. Greater forces tend to stretch or distort the plastic material which could lead to future rupture. Do not use pipe wrenches, locking channel pliers or vise-lock pliers; all of these create stress in the molecular structure of the plastic. Do not connect to a metal pipe. This could cut into the plastic and also cause a future rupture.

The Series "GYW" (wafer design) flow indicators simply slip between two smooth faced companion flanges that may be either metal or plastic. Flange gaskets are not required as these flow indicators are supplied with two O-rings for just that purpose. Care should be taken so there is no misalignment of the flanges. Flange bolts should be tightened gradually alternating between opposite bolts to insure that the assembly pulls together evenly. The final 1/16" of tightening should be done with a torque wrench set between 10 and 15 foot pounds. This will seal the O-rings without placing uneven or excessive stresses on the assembly.

Although these flow indicators have no specific inlet or outlet, care should be exercised when installing such units that have streamers for fluttering devices. They must be installed in such a manner that the fluid flow will force the streamers into the indicator's viewing area.

The Series "GL" level indicators, usually mounted on the outside of a tank wall, must be installed vertically and are supplied with female threads. Refer to "GX" and "GY" installation instructions. In addition, it is advisable to connect these level indicators to a tank with true-union ball valves. This way the level indicators may be removed from the piping for cleaning or inspection while there is still liquid at that level in the tank.

Although the Series "GL" level indicators are only available up to a maximum nominal length of 4 feet, they can be installed on tanks of greater heights. In this case it is recommended that they be installed in a staggered position where the visual length is uninterrupted. This type of installation will eliminate any visual dead spots. Do not connect them together with pipe nipples as it will create visual dead spots and an unstable assembly.

Thông số kỹ thuật

Plast-O-Matic offers to customers a wide choice of plastic indicator end materials is offered to assure maximum chemical compatibility.

Connection end material:

- Series "GX" Sight Glasses: PVC (TYPE 1, GRADE 1 PVC) or Polypropylene (PP).

- Series "GY" Sight Glasses and Series "GL": Geon® PVC, Polypropylene (PP), or PTFE.

- Series "GYW" Sight Glasses: PVC, Corzan® CPVC, Polypropylene (PP), PTFE or Kynar PVDF®.

O-Ring seals material:

Series "GX" indicators Sight Glasses: Buna-N or Viton®.

Series "GY," "GYW" and "GL" indicators: Viton O-rings are standard.

Standard fasteners are stainless steel on Series "GX", "GY" and "GYW" flow indicators. Fasteners are not used on Series "GL" level indicators.

Cylinder wall material:

The transparent inner walls in the Series "GY", "GYW" and "GL" indicators: Pyrex®.

The transparent outer walls: high impact strength Acrylic.

.gif)