Van một chiều rắc co nhựa SPEARS

Since 1969, Spears® Manufacturing Company has developed high quality thermoplastic piping system components to better meet industry needs. Spears® thermoplastic valves have been developed through years of product improvement testing, combined with the latest in computer aided engineering and manufacturing technology. Today, Spears® valves are recognized for their quality, reliability and long service life. Backed by the best in customer service and product availability, Spears® valves are the first choice for use in a wide variety of applications, including Industrial & Chemical Processing, Turf & Irrigation, Pool & Spa, and numerous Original Equipment Manufacture products.

Check valves are automatic valves that open with forward flow and close with reverse flow. Exact operation will vary depending on the type of check valve mechanism. These include a ball (Ball Check), a swinging disc (Swing Check), a “double disc” (Butterfly Check), a weighted plug (Y-Check), and spring assisted types of check devices. These include a spring assisted swinging disc (Spring Check) and a spring mounted linear disc (In-Line Spring Check). Regardless of type, a check valve has a closure device positioned in the valve body between inlet and outlet so that the fluid stream is easily transmitted in the direction of flow, but is allowed to move against the check device in the event of flow in the reverse direction. Reversed flow is stopped or held in “check” by fluid backflow pressure which seats the closure device against the valve body. Standard elastomer O-ring seals are used in all Spears® Ball Check Valves and Industrial Swing Check Valves. Utility Swing and Spring Check Valves, and Butterfly Check Valves use an elastomer membrane seal; In-Line Spring Check Valves and Y-Check valves use an elastomer seat. Spears® Check Valves have been carefully engineered to minimize pressure drop and can be installed in either horizontal or vertical positions, within the limitations of the specific type of closure device. Ball Check Valves are well suited for general applications of fluids free from debris and entrained solids. Butterfly Check Valves have minimum space requirements and, along with Swing Check Valves, are better for use with fluids containing solids or debris. Swing Check Valves additionally allow higher volume of fluid transmission. Industrial Swing Check models can be fitted with an optional counter balance device to further control closing speed. The Utility Spring Check Valve (spring assisted Swing Check) aids in valve closing, while the In-Line Spring Check can be adjusted for resistance to opening pressure.

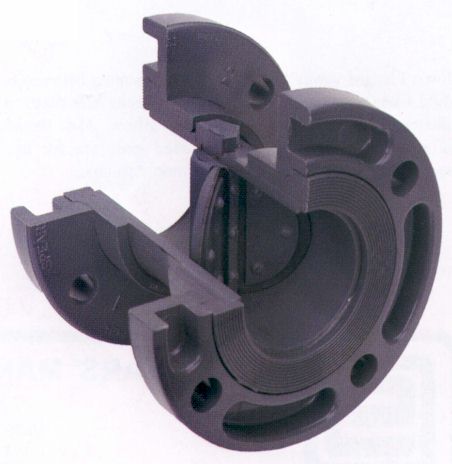

True Union 2000 Industrial Ball Check Valves

Flow tested design provides quick response with positive seal for prevention of system back flow in industrial and chemical processing applications. Valves are available in IPS sizes 1/2" through 6" with socket/regular thread, SR threaded (Special Reinforced), flanged or spigot end connectors and 8" venturied valve with socket or flanged ends. Also available in metric socket and BSP thread sizes 1/2" through 2".

Features:

• Chemical & Corrosion Resistant PVC or CPVC Construction

• Also Available in Spears® High Purity, Low Extractable PVC Material

• Strong, Buttress Thread Union Nuts

• Spears® Safe-T-Blocked® Seal Carrier

• Uses Standard O-ring Seat

• EPDM or FKM O-rings

• Fully Serviceable, Replaceable Components

• Sizes 1/2" - 4" Pressure Rated to 235 psi @ 73°F, Sizes 6" and 8" Venturied and all Flanged Pressure Rated to 150 psi @ 73°F

• Suitable for Either Horizontal or Vertical Installations

• EPDM valves NSF® Certified for Potable Water use

• Suitable for Vacuum Service

• Assembled with Silicone-Free, Water Soluble Lubricants

• Manufactured to ASTM F 1970

Industrial Swing Check Valves

Designed for optimum flow, quick response and positive shutoff with minimum turbulence, this industrial grade Swing Check Valve is used in a variety of industrial and chemical processing applications where high volume fluid transfer is required. Suitable for horizontal or up-flow vertical applications. Available in PVC, CPVC and Glass Filled Polypropylene, IPS 3/4" - 8" with Flanged Body. Engineered for Quick Response, Full-Flow Fluid Transfer

Features:

• Heavy Bodied All-Plastic Interior Construction

• Top Access & O-ring Sealed Drain Plug for In-line Servicing

• Standard O-ring type Seat & Seals in EPDM or FKM

• Sizes 3/4" - 4" Pressure Rated to 150 psi @ 73°F, 6" Pressure Rated to 100 psi and 8" to 70 psi @ 73°F

• Stainless Steel External Hardware

• Fully Serviceable, Replaceable Components

• Suitable for Vacuum Service

• Assembled with Silicone-Free, Water Soluble Lubricants

True Union Utility Swing Check or True Union Utility Spring Check

Spears® True Union Utility Swing Check and spring assisted True Union Utility Spring Check Valves offer a compact, high performance check valve for Landscape & Irrigation, Pool & Spa, Aquaculture, OEM 1 and many general purpose applications. True Union design allows for easy in-line replacement of maintenance free sealed units. These valves feature long-life EPDM elastomer seats with weighted disc for full-flow with minimal restriction and positive shutoff. Spring assisted “Spring Check” model incorporates a positive-pressure spring to assist in valve closing without slamming. Produced from PVC White or PVC Clear material with Socket, Threaded or SR Threaded end connectors in IPS Sizes 1/2" through 4".

• Chemical & Corrosion Resistant PVC White or High Visibility PVC Clear Construction

• No Metal Parts on Swing Check - Stainless Steel Spring on Spring Check

• True Union style for Easy In-line Replacement of Sealed Unit

• Strong Buttress Threaded Union Nuts

• Engineered for Maximum Flow, Quick Response & Positive Shutoff

• Long-Life, High Grade EPDM Seat with Weighted Disc

• Spring Assisted Spring Check Model Option for Positive Closing

• Pressure Rated to 150 psi @ 73°F Full-Flow (open) and 75 psi @ 73°F Back Pressure (closed)

• Suitable for either Horizontal or Vertical Up-flow Installations and Vacuum Service

• NSF® Certified for Potable Water Use

• Silicone-Free Assembly

General Installation Information: True Union Swing Check valves are designed for horizontal installations, but may be installed in up-flow only vertical position. Check valves MUST be installed with the valves FLOW arrow pointing in the direction of the flow. Do not install valve upside down. Flow velocity should not exceed 5ft./sec. Minimum opening pressure less than 0.5 psi.

Utility Swing & Spring Check Valves

Spears® Utility Swing Check and spring assisted Utility Spring Check Valves offer a compact, high performance check valve for Landscape & Irrigation, Pool & Spa, Aquaculture, OEM and many general purpose applications. These maintenance free sealed units feature long-life EPDM elastomer seats with weighted disc for full-flow with minimal restriction and positive shutoff. Spring assisted “Spring Check” model incorporates a positive-pressure spring to assist in valve closing without slamming. Produced from PVC White or PVC Clear material with Socket, Threaded or SR Threaded end connectors. Available in IPS Sizes 1/2" through 8" for Swing Check Valves and 1/2" through 4" for Spring Check Valves.

• Chemical & Corrosion Resistant PVC White or High Visibility PVC Clear Construction

• No Metal Parts on Swing Check - Stainless Steel Spring on Spring Check

• Maintenance Free Sealed Unit in a Compact Space Saving Design

• Engineered for Maximum Flow, Quick Response & Positive Shutoff

• Long-Life, High Grade EPDM Seat with Weighted Disc

• Spring Assisted Spring Check Model Option for Positive Closing

• Sizes 1/2" – 4" Pressure Rated to 150 psi @ 73°F Full Flow (open) and 75 psi @ 73°F Back Pressure (closed)

• Sizes 6" – 8" Pressure Rated to 100 psi @ 73°F Full Flow (open) and 50 psi @ 73°F Back Pressure (closed)

• Suitable for either Horizontal or Vertical Up-flow Installations and Vacuum Service

• NSF® Certified for Potable Water Use

• Silicone-Free Assembly

General Installation Information: Utility Swing check valves are designed for horizontal installations, but may be installed in up-flow only vertical position. Check valves MUST be installed with the valves FLOW arrow pointing in the direction of the flow. Do not install valve upside down. Flow velocity should not exceed 5ft./sec. Minimum opening pressure less than 0.5 psi.

Y-Check Valves

Spears® Y-Check Valves are an angle type check valve that automatically stops reverse flow by the dead weight of the disc plug. Y-checks are less affected by turbulent flow and typically have lower shutoff characteristics than ball checks. Valves are available in PVC Gray, PVC Clear, and CPVC materials in IPS Sizes 1/2" through 4" with Socket, SR Threaded or Flanged end connections, plus True Union styles with Socket and SR Threaded ends.

• Chemical & Corrosion Resistant PVC, PVC Clear, and CPVC Construction

• Improved Flow Characteristics Over Ball Checks, Outperforms Spring Loaded Designs

• Easy Access Cap for In-Line Clean Out & Servicing

• Optional True Union Design for Easy Valve Service Replacement

• Standard O-ring type EPDM or FKM Seat & Seals

• Sizes 1/2" – 2" Pressure Rated to 150psi @ 73°F, Sizes 3" – 4" Pressure Rated to 90 psi @ 73°F

• Suitable for either Horizontal or Vertical Up-flow Installations

• Assembled with Silicone-Free, Water Soluble Lubricants

Butterfly Check Valves

This multi-purpose check valve provides an extremely low profile and very quick response to back flow without slamming. Since most all components are internal, Spears® Butterfly Check Valves require no more space than a piece of pipe and fitting. Special design incorporates flexible reinforced elastomer seal for long life and is suitable for mounting in any position for greater versatility. Available in IPS sizes 2" - 12" with Flanged, Spigot, Male Threaded, Grooved Pipe style & Wafer end connections, and 14" - 24" Flanged, Spigot, Grooved & Wafer end connections. Can be custom produced to virtually any standard pipe diameter.

• Chemical Resistant PVC & CPVC Construction

• No Metal Components

• Quick Response Shut-off In Any Position

• Replaceable Internal Components - Choice of Reinforced EPDM or FKM

• Suitable for Horizontal or Vertical Installation

• Sizes 2" - 8" Pressure Rated to 150 psi for water at 73°F

• Sizes 10" - 14" Pressure Rated to 100 psi for water at 73°F

• Sizes 16" Pressure Rated to 70 psi for water at 73°F

• Sizes 18" - 24" Pressure Rated to 50 psi for water at 73°F

• Assembled with Silicone-Free, Water Soluble Lubricants

Diaphragm Check Valves

Spears® Diaphragm Check Valves do not depend on gravity, springs, or even reverse flow to seat. Resilient thermoplastic elastomer (TPE) diaphragm is the only moving component, which automatically seats when flow stops. No sticking, no chatter. This specialty elastomer exhibits high flex and tear resistance to provide excellent durability and long life. Valves are available in PVC and CPVC material size of 3/4" with socket and threaded end connections.

"Normally Closed” operation is excellent for applications with low seating pressure

• Low cracking pressure, 1 to 1-1/2 psi

• Leak-free, silent operation

• Installs just like a Union – in ANY position

• Pressure rated to 150 psi full-flow (open), 100 psi back pressure (closed) for water @ 73°F

• Santoprene™ TPE diaphragm seat provides extended life and durability – fully serviceable and replaceable

• All materials are NSF® Certified for use with potable water

In-Line Adjustable Spring Check Valves

Adjustable feature allows control of back pressure in system, reduces water hammer, and prevents siphoning. Easily adjusts to hold back from 5 to 32 feet of pressure head, 1 psi (2.3 feet of head) for each full turn of the adjustment screw. Ideal for landscape and irrigation applications, quickly installs with space saving in-line design.

• 2 - 14 lbs. Adjustable Spring Tension (5 to 32 feet of head) Factory Preset to Approx. 5 psi (12 feet of head)

• Stainless Steel Adjustment Spring with EPDM Seat

• Pressure Rated to 200 psi for Water @ 73°F

• Standard Unit Available in 1/2", 3/4", 1" & 1/2" x 3/4" with Fipt Inlet x Mipt Outlet Configuration

• Plus, Popular Configuration Options of 1/2" Mipt Inlet x Fipt Outlet & 3/4" Fipt Inlet x Fipt Outlet

Thông số kỹ thuật

All thermoplastic check valves shall be manufactured to ASTM F 1970 and constructed from PVC Type I, ASTM D 1784, Cell Classification 12454 or CPVC Type IV, ASTM D 1784 Cell Classification 23447. All O-rings shall be EPDM or FKM. All valve union nuts shall have Buttress threads. All valve seats shall be a standard O-ring type. All seal carriers shall be Safe-T-Blocked®. All valve components shall be replaceable. All EPDM valves shall be listed by NSF® for use in potable water service. All PVC and CPVC 1/2" through 4" valves shall be pressure rated to 235 psi, all 6" and 8" Venturied and all flanged valves shall be pressure rated to 150 psi for water at 73°F as manufactured by Spears® Manufacturing Company.